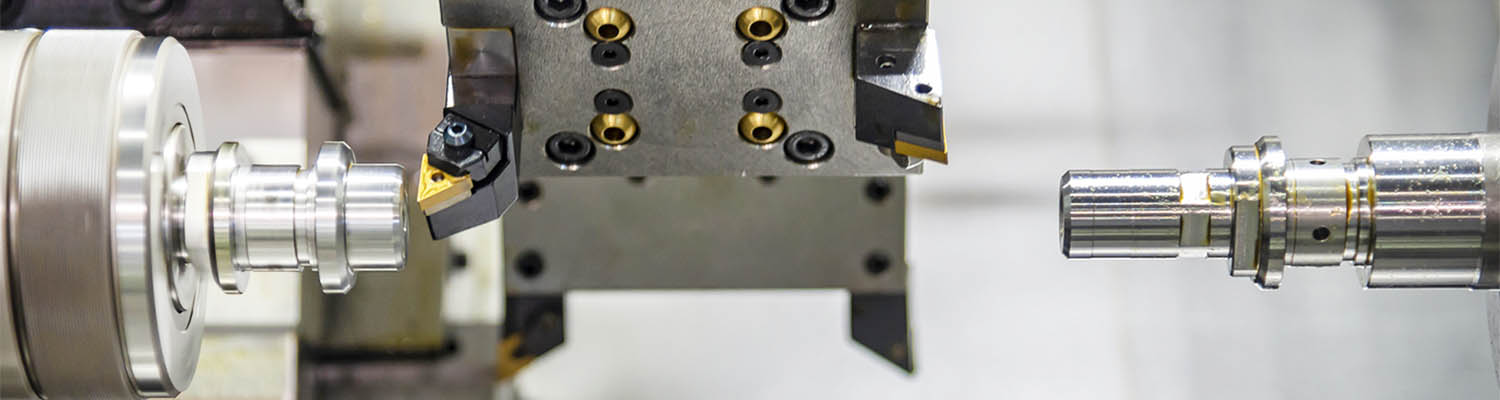

Cutting

Using a machining center and NC lathe, each aluminum material is finished to the product required by the customer with higher accuracy.

We introduce high-quality processing to the procurement power which was cultivated for many years as the material business company and provide highly value-added processed products. The infield of the car, the electricity, the fabric, and the food and so on, it contributes to the totaled cost reduction and it receives a high evaluation.

Using a machining center and NC lathe, each aluminum material is finished to the product required by the customer with higher accuracy.

Drilling and notches are performed by pressing using a press die. We can handle lots with large numbers.

Casting: Make molds close to the required products, then cast aluminum that has been heated to high temperatures, and harden it. / Forging: Stamping a lump of aluminum.

These make it possible to manufacture parts with complex shapes, and forging is suitable for mass production of automobile parts.

High precision machining is desired for precision parts used in semiconductor manufacturing equipment. In addition, we will be able to consistently respond to hard coating surface treatment.

Since inheriting the patent of "New hard aluminum oxide coating method“ from Nippon Light Metal Co., Ltd. in 1965, our technology has been getting a large evaluation in a usage that corrosion resistance, electrical insulation properties, and heatproof, etc. by the hard and thick coat, because it is different from the coating which is only thick anodized aluminum.

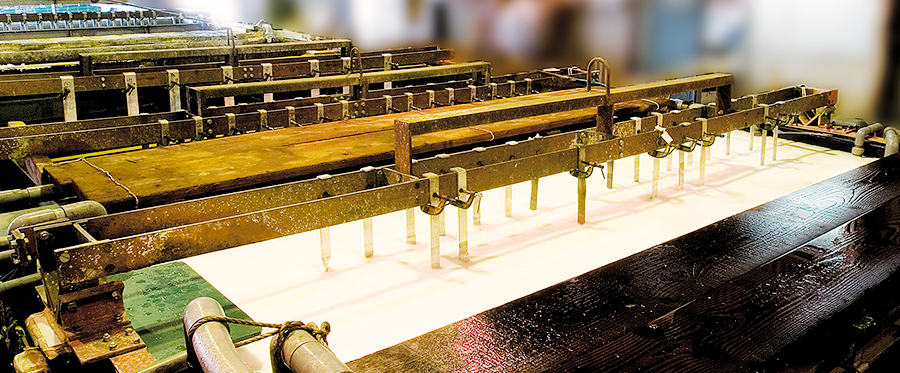

Beverage cans are becoming more popular with the spread of vending machines and lifestyle changes-especially for beer and carbonated beverages, the demand for aluminum cans is growing significantly.

Efficient aluminum can manufacturing technology has been established, and it is widely known that it has no can odor, cools quickly, is beautifully printed, is lightweight and easy to transport, and is useful for saving energy and resources through recycling. Now, aluminum cans are the mainstream.

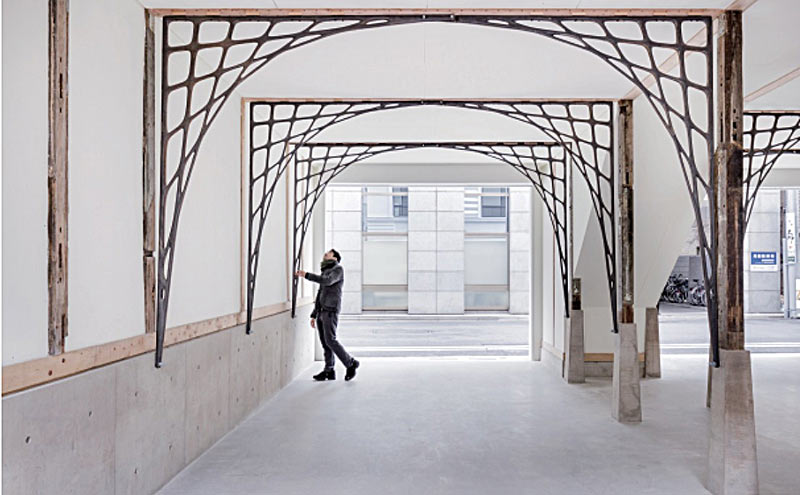

Aluminum is a beautiful metal as it is, but it can be made more beautiful by applying various surface treatments such as anodizing treatment, and it can harden the surface and enhance the anticorrosion effect. Various colors can be applied to aluminum by natural coloring or electrolytic coloring during anodic oxide coating treatment, and it is the most suitable material for fields that require designability strongly such as building exteriors and packaging materials.

Aluminum has properties such as "low melting point", "even when melted, the surface is covered with an oxide film and hardly absorbs gas", and " melted fluidity is good". This makes it possible to produce thin-walled castings and castings with complex shapes.

Aluminum castings are used in a wide range of fields, including automotive parts such as pistons, cylinder blocks, and wheels, as well as various industrial machine parts.

Please feel free to contact us if you have any new ideas on efficiency and product development using aluminum materials. Tomisho’s staff will work together to create the most suitable product for customers.